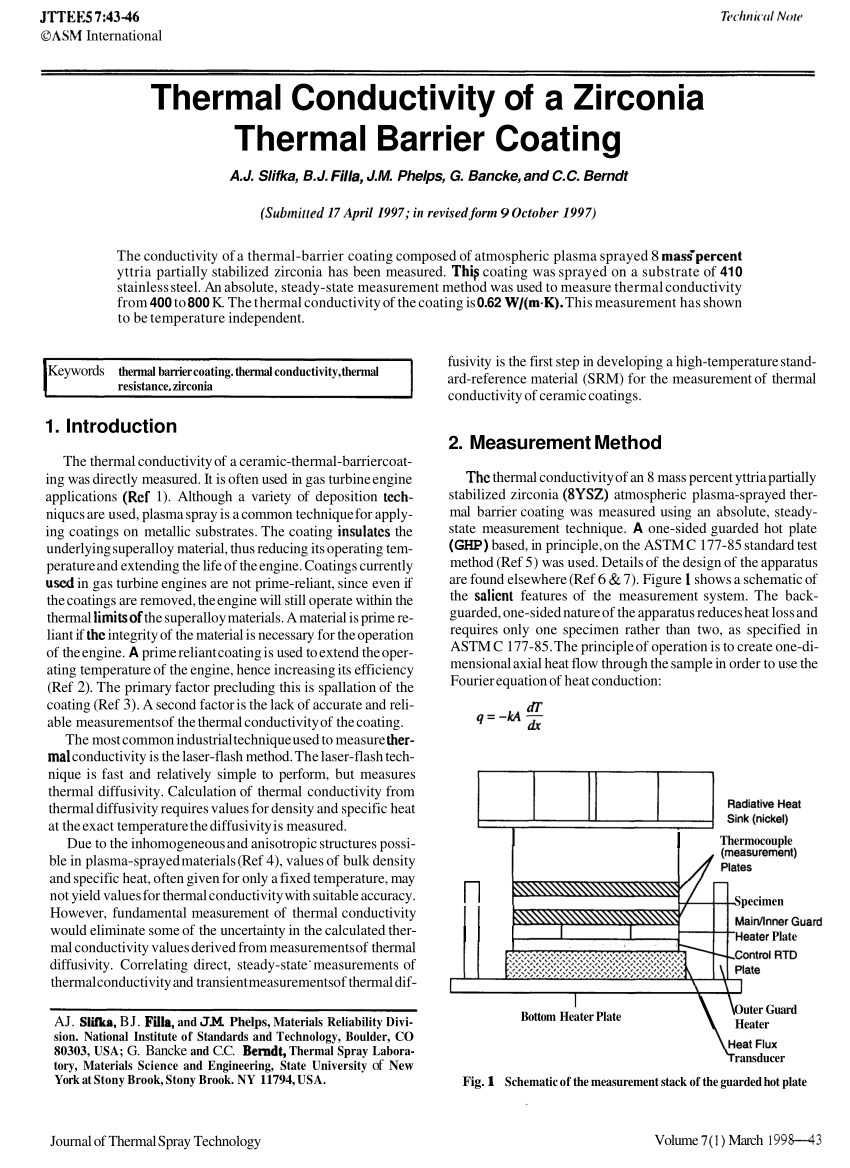

Some ceramic materials possessing low thermal conductivities have been used as thermal barrier coating tbc materials to increase turbine inlet temperatures since the 1960s.

Ceramic thermal barrier coating materials.

We are also experts in plasma spray processing and the production of high performance surface coatings and finishes.

Devices such as engine turbine blades can operate at high temperatures and can increase the thermal efficiency of devices engines etc by more than 60.

We are specialists in heat management.

Silica at the grain boundaries leads to changes in the size and shape of grains and it may dissolve y 2 o 3 from the ysz grain boundary regions.

Institut für werkstoffe und verfahren der energietechnik forschungszentrum jülich gmbh d 52425 jülich germany.

Search for more papers by this author.

The silica impurity even as low as 1 wt in ysz coating has a strong detrimental effect on the thermal cycling life 44 45 in bulk zirconia based ceramics silica segregates to grain boundaries with excessive amounts collecting at triple points.

Author links open overlay panel w.

The coating insulates the substrate material and lowers the substrate temperature.

Zirconates with high melting points were investigated for application as materials for thermal barrier coatings at operating temperatures 1300 c.

Thermal barrier coating tbc is a coating made of ceramic materials deposited on the surface of a high temperature resistant metal or superalloy.

With increasing engine efficiency they can reduce metal.

Although the common ysz ceramic materials can meet the thermophysical properties and phase stability requirements of the thermal barrier coating at around 1000 c ysz is unable to meet the needs.

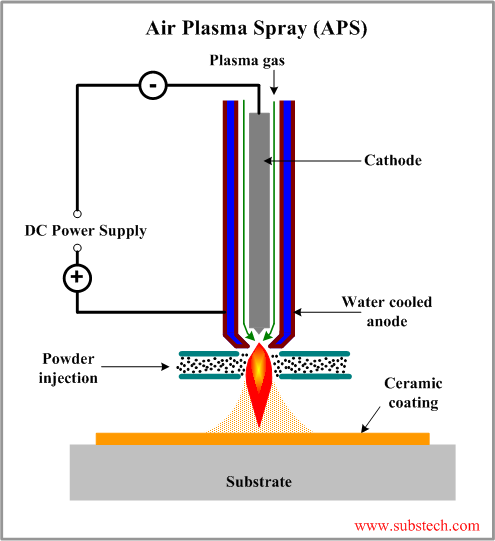

Although most ceramic coatings are applied to metallic parts directly related to the engine exhaust system technological advances now allow thermal barrier coatings to be applied via plasma spray onto composite materials.