Stock bars and sheets of cold rolled steel crs are commonly used in all areas of manufacturing the terms are opposed to hot formed steel and hot rolled steel.

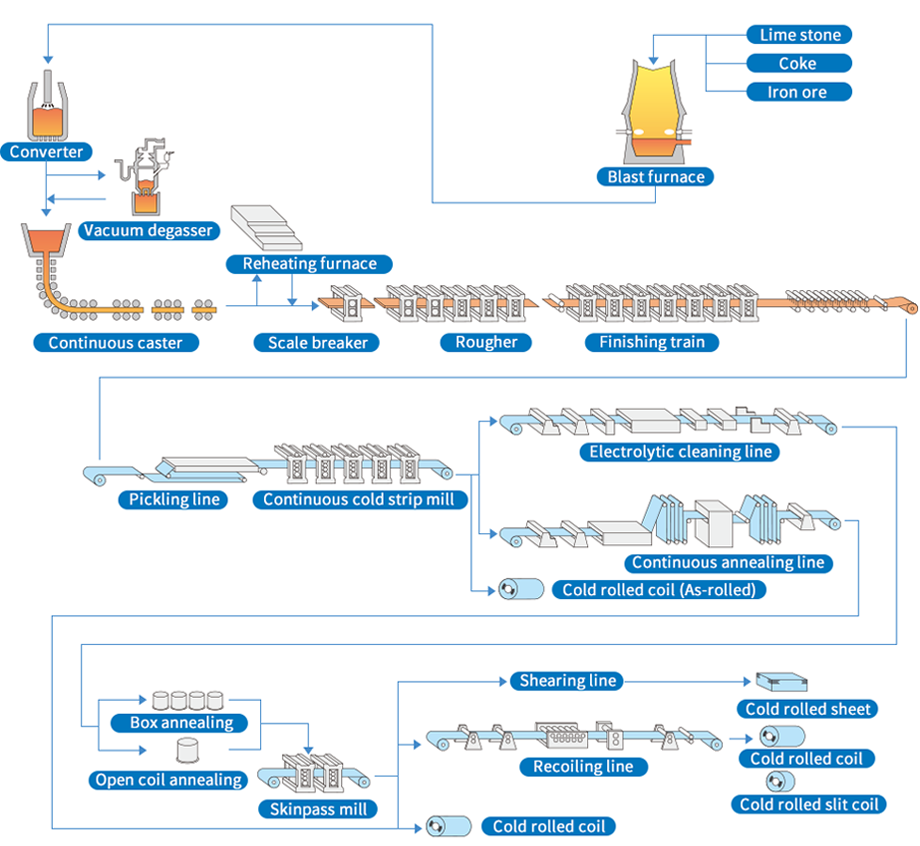

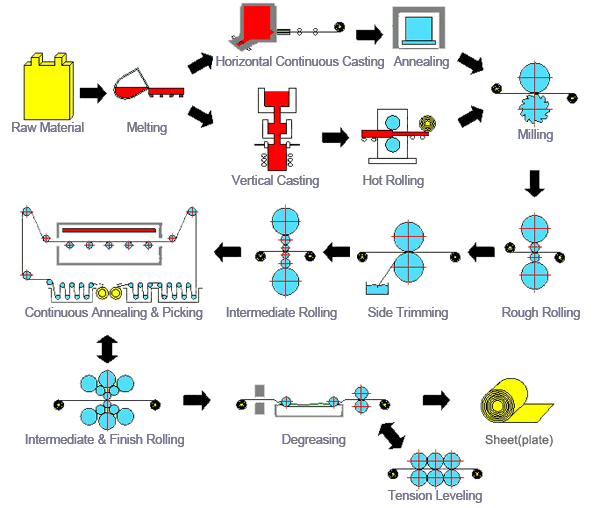

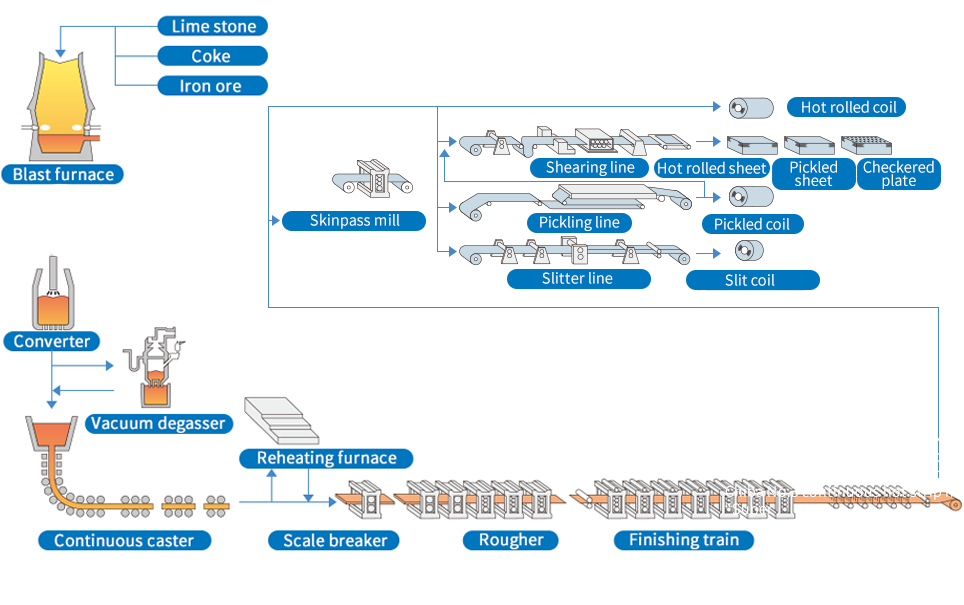

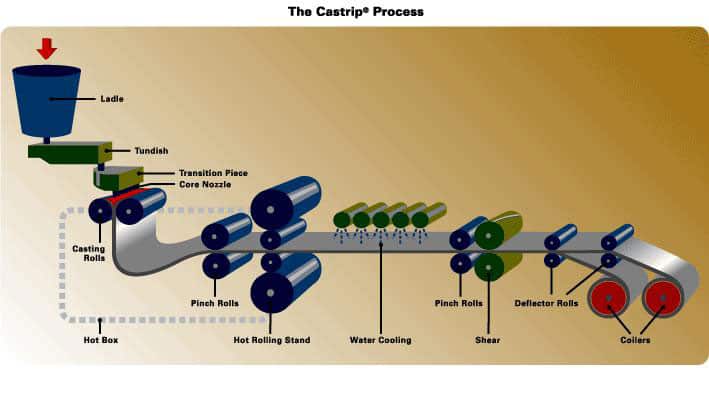

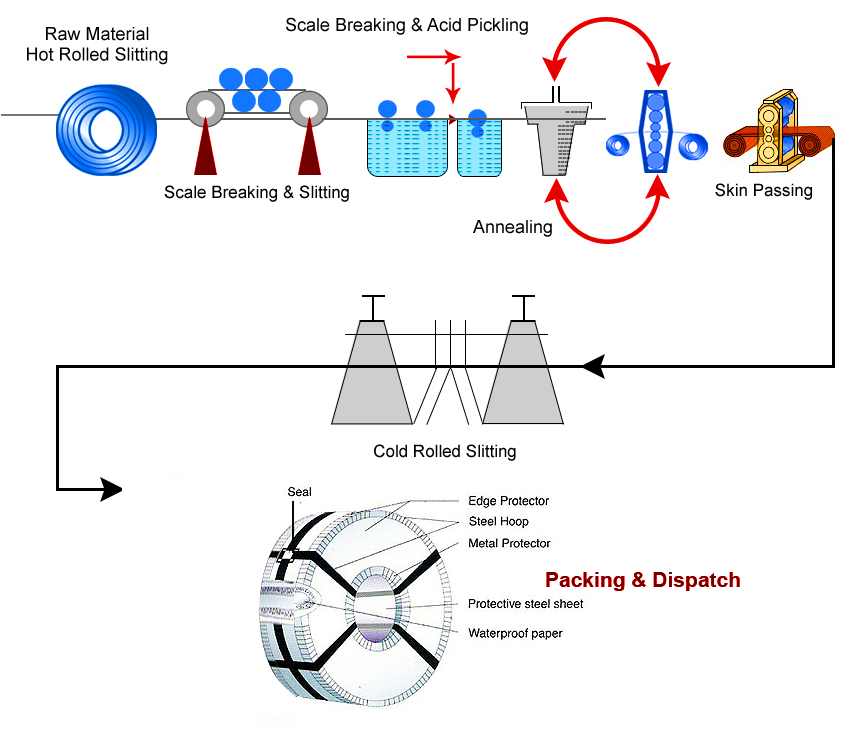

Cold rolled steel sheet manufacturing process.

Cold rolling causes steel to become hard and brittle.

The vijayanagar plant of jsw steel is the first integrated steel plant to reach 10 mtpa capacity at a single location in india.

As you might suspect the manufacturing process behind cold rolled steel is a bit different.

Coils can achieve homogeneous qualities and higher production rate due to higher heat transfer.

Choose from our selection of cold rolled steel including low carbon steel sheets and bars low carbon steel rods and discs and more.

To obtain the desired microstructure and improve mechanical properties the cold rolled strip is annealed at the suitable temperatures.

The amount of strain introd.

Despite the name this process refers to steel that is pressed with the pressure of a roller at room temperature.

Hot rolling is a mill process which involves rolling the steel at a high temperature typically at a temperature over 1700 f which is above the steel s recrystallization temperature.

In terms of usage hot rolling processes more tonnage than any other manufacturing process and cold rolling processes the most tonnage out of all cold working processes.

Cold formed steel especially in the form of thin.

Cold rolling is a process that occurs after hot rolling in order to reduce the thickness increase the yield and tensile strength and pliability of metal.

It is a relatively expensive and labour intensive process but the improved mechanical properties increase the value of the finished product whether that is a sheet strip or coil.

Cold rolled sheet is produced from a precisely manufactured hot rolled processed sheet which is then cold reduced to the desired thickness.

Cold formed steel cfs is the common term for steel products shaped by cold working processes carried out near room temperature such as rolling pressing stamping bending etc.

In stock and ready to ship.

Compared to hot rolled steel cold rolled steel has a nearly 20 increase in strength through the use of strain hardening.

Cold rolled steel is a more highly finished product and has a smoother surface greater dimensional accuracy thickness width length and greater strength.

It is the first plant in india to use the corex technology for hot metal production.

Widest cold rolling mill for automotive steel in india.

When steel is above the recrystallization temperature it can be shaped and formed easily and the steel can be made in much larger sizes.